Aim

Currently, heat generated by CPUs is dissipated in air coolers - a waste.

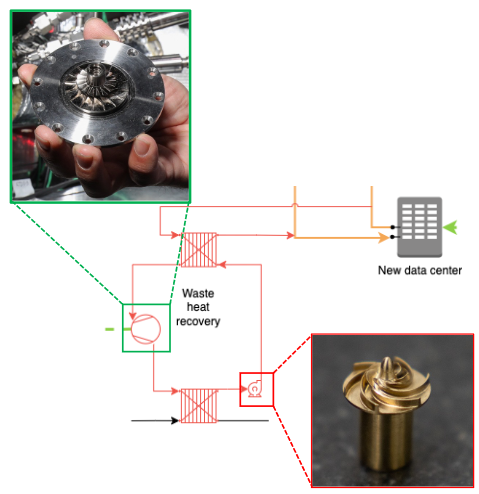

This activity is dedicated to the waste heat recovery of the CPUs' cooling system. This will be achieved by developing an optimized and fully operational Organic Rankine Cycle (ORC) that can provide electrical power using waste heat from the CPUs.

The CPUs' waste heat extracted at 75°C (See Heat recovery and electricity generation) will be led into the ORC, which will transform part of that heat into electricity and dump the devalorized heat through a condenser to the EPFL cooling network at 10°C. Considering a nominal processor power of 50kW, the turbine will provide 4-5kW of net electrical power that will be injected into the direct current power distribution bus of the DC.

Technological roadmap

For the implementation of this activity, the following steps will be undertaken:

Phase 1: Design of the ORC

1. Integrated cycle sizing and optimization

• Pre-design of turbine, turbopump, nominal and part-load

• Cycle layout, working fluid selection, heat exchanger design

2. Turbomachinery system design

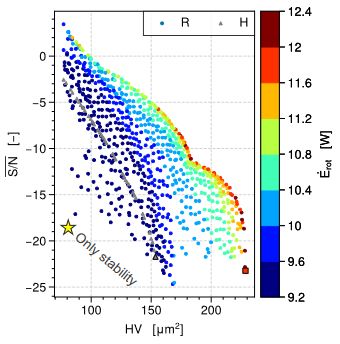

• Formulate design as multi-objective optimization problem

• Concept of design robustness to identify resilient solutions

• Hierarchy of ROM for the different design phases

Phase 2: Development and deployment of the ORC

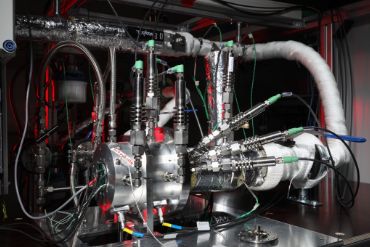

3. Development & commissioning

4. Experimental validation

• Component test, cycle characterization, coupled to DC

Novelty

System design

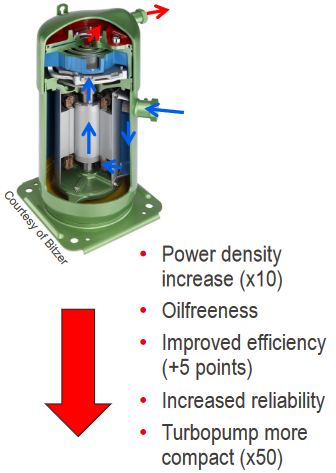

• First oil-free ORC with single-stage turbine and turbopump

• Smallest known oilfree radial inflow turbine for 5kW

• Extend concept of design robustness to system design

Turbomachinery design

• Adjoint-base optimization of turbine with potentially supersonic flow, variable nozzles, dense gases

• Small-scale effects in radial inflow turbines and pumps

• Unique experimental data for model refinement

Bearings & rotor dynamics

• Asymmetric grooves to decrease rotor windage losses

• Enhanced bearing grooves for real gas environment